Integrating Cutting-Edge Technology

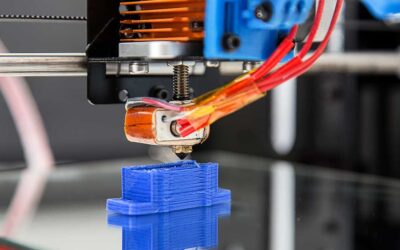

One of the foremost challenges in manufacturing engineering systems is the integration of cutting-edge technologies. The fourth industrial revolution, often referred to as Industry 4.0, has brought about a wave of new technologies such as the Internet of Things (IoT), artificial intelligence, robotics, and additive manufacturing. These technologies have the potential to revolutionize manufacturing processes, but integrating them into existing systems is a Herculean task. Many manufacturing facilities have legacy equipment and systems that may not be compatible with new technologies. Retrofitting or upgrading these systems requires significant capital investment, and there’s also the challenge of ensuring that the new technologies can communicate and work effectively with existing systems.

Cybersecurity

Another technological challenge is cybersecurity. As manufacturing systems become more connected through IoT and cloud technologies, they become more vulnerable to cyberattacks. Protecting the intellectual property and ensuring the integrity of manufacturing processes is paramount, as any breach can have catastrophic consequences. Moreover, with the rising trend of remote working and global supply chains, ensuring secure communication channels is also a complex challenge.

Customization

The advent of customization and personalization in product design is placing enormous demands on manufacturing engineering systems. Traditionally, manufacturing was geared towards mass production – producing large quantities of standardized products. However, modern consumers increasingly demand products that are customized to their preferences. Manufacturing systems must be agile and adaptable to produce small batches of customized products without losing economies of scale. This requires sophisticated production planning and control systems, as well as flexible manufacturing equipment that can be quickly reconfigured for different products.

Quality Control

Quality control is another significant challenge. As manufacturing processes become more complex, ensuring that products meet quality standards is not trivial. Traditional quality control methods, which often rely on inspecting products after they have been manufactured, are not sufficient. There’s a need for more sophisticated quality control systems that can monitor manufacturing processes in real-time and make adjustments on the fly to ensure quality. Implementing such systems requires advanced sensors and data analytics tools, as well as integrating these tools into the manufacturing process.

Sustainability and the Environment

Sustainability and environmental concerns are also increasingly pressing issues. Manufacturing processes are often resource-intensive and can have a significant environmental impact. There’s growing pressure from governments, consumers, and other stakeholders for manufacturers to reduce their environmental footprint. This includes reducing waste, minimizing energy consumption, and ensuring that materials are sourced sustainably. Achieving sustainability is particularly challenging because it often involves trade-offs. For example, using more sustainable materials may increase costs or reduce product performance.

Workforce Management

Workforce management and skills development is another challenge that should not be underestimated. The new technologies and methodologies employed in modern manufacturing systems require a highly skilled workforce. However, there is often a skills gap, as the education system may not be producing graduates with the skills needed in modern manufacturing. Additionally, there’s the challenge of retraining the existing workforce, who may have skills that are becoming obsolete. Workforce management also includes ensuring worker safety, particularly as manufacturing systems incorporate more robotics and automation, which can pose new safety risks.

The Supply Chain in a Global World

Managing global supply chains adds another layer of complexity to the challenges of manufacturing engineering systems. Many manufacturers source materials and components from suppliers around the world, and may also have manufacturing facilities in multiple countries. Managing these global supply chains is incredibly complex, particularly in an ever-changing global economic environment. Factors such as trade regulations, currency fluctuations, and geopolitical tensions can all impact supply chains, and manufacturers must be agile in adapting to these changes.

Addressing the Challenges

Manufacturing engineering systems stand at the crossroads of technology, management, and global economics. The challenges in dealing with the incorporation of cutting-edge technologies, cybersecurity, customization, quality control, sustainability, workforce management, and global supply chain complexities are monumental. It is essential for manufacturers to adopt a holistic approach that encompasses continuous innovation, strategic planning, and agility.

One of the key facets of addressing these challenges is fostering a culture of lifelong learning and adaptation within the organization. The rapid pace of technological change necessitates that both the management and the workforce are perpetually equipped with the latest skills and knowledge.

Collaboration is another critical element; manufacturers should actively engage with technology providers, educational institutions, governments, and other stakeholders. This synergy can drive the development of solutions that are more robust and tailored to the unique challenges faced by the industry.

Leveraging data analytics and artificial intelligence can be a game-changer in optimizing manufacturing processes, enhancing cybersecurity, monitoring quality, and predicting and mitigating supply chain disruptions. These tools can provide invaluable insights and facilitate more informed decision-making.

Sustainability should be ingrained in the core values of the organization. Manufacturers should not view sustainability as merely a regulatory compliance issue but as a fundamental component of their long-term strategy. Sustainable practices can often lead to cost savings in the long term and enhance the brand image, which is increasingly important in a market where consumers are becoming more environmentally conscious.

Ultimately, navigating the labyrinth of challenges in manufacturing engineering systems requires a blend of technological prowess, strategic vision, collaboration, and an unwavering commitment to continuous improvement and sustainability. Those manufacturers who can adeptly maneuver through these challenges are poised not only to thrive but also to lead the vanguard in the evolution of the manufacturing industry.