An In-depth Examination of the Boon and Bane of Additive Manufacturing in the Engineering Landscape

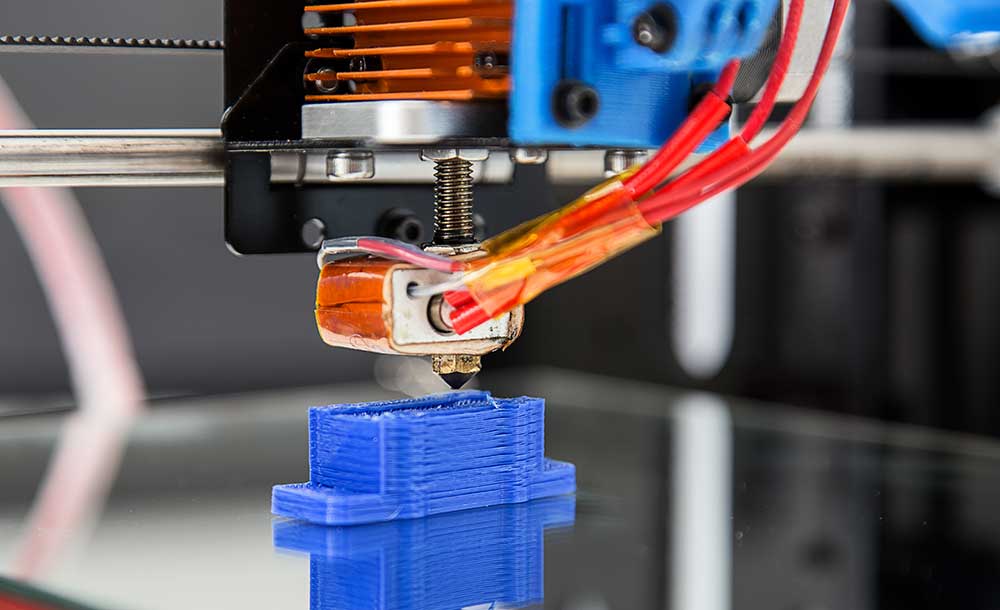

Additive manufacturing, commonly known as 3D printing, is revolutionizing the manufacturing sector. As the technology evolves, it has become a hot topic among manufacturing engineers. Additive manufacturing is hailed as a game-changer with the promise of flexibility, reduced costs, and customization. However, concerns regarding quality, environmental impact, and job displacement arise along with its merits. In this comprehensive analysis, we weigh the pros and cons of adopting additive manufacturing.

The Allure of Additive Manufacturing:

Additive manufacturing has gained momentum for several reasons:

- Design Freedom: One of the most significant advantages is the design freedom it offers. Traditional manufacturing techniques no longer constrain engineers and can create complex, intricate designs without additional costs.

- Customization: The ability to produce custom-designed products on demand is invaluable, especially in industries such as healthcare, where patient-specific implants and prosthetics can be manufactured.

- Supply Chain Simplification: Additive manufacturing can simplify supply chains by reducing the need for various manufacturing steps and tooling and even allowing for onsite production.

- Material Efficiency: By building objects layer by layer, material wastage is minimized, and in some cases, excess material can be reused.

- Rapid Prototyping: Engineers can quickly produce prototypes for testing and evaluation, significantly accelerating product development cycles.

The Shadows Behind the Silver Lining:

However, additive manufacturing also casts shadows that cannot be overlooked:

- Quality and Consistency: While 3D printers have improved, consistency and quality, particularly for high-performance parts, remain a concern. Defects such as porosity or uneven cooling can compromise the structural integrity of the components.

- Environmental Impact: Although material efficiency is a benefit, the energy consumption of additive manufacturing processes, especially for metal-based printing, is high. The environmental footprint, in terms of energy consumption, can be significant.

- Job Displacement: Automated additive manufacturing processes require less manual labor, leading to concerns about job displacement within the manufacturing sector.

- Intellectual Property Concerns: The ease with which products can be replicated using 3D printers raises concerns about intellectual property protection and piracy.

- Limited Materials: The range of materials suitable for additive manufacturing is growing but still limited compared to traditional methods. This limits the applications and can affect material properties like tensile strength.

A Balanced Perspective:

With these factors in mind, engineers and decision-makers must adopt a balanced perspective. For instance, integrating additive manufacturing for rapid prototyping and customized components while relying on traditional manufacturing for large-scale production can harness the strengths of both worlds.

Further, addressing the shadows requires innovation. Research into enhancing the quality and consistency of 3D-printed parts is ongoing. Advancements in renewable energy sources could mitigate the environmental impact. Focusing on upskilling and retraining the workforce can help address job displacement concerns.

Promise or Pitfall?

As dazzling as it is, additive manufacturing holds both promise and pitfalls. It presents manufacturing engineers with unparalleled freedom in design and customization but challenges them with quality, environmental impact, and socio-economic implications. As stewards of technology, engineers must navigate this double-edged sword judiciously. Continuous innovation, sustainability considerations, workforce development, and ethical practices should be the guiding lights as additive manufacturing continues to shape the future of manufacturing engineering.