Mechanical engineering stands as one of the most foundational and expansive disciplines within the engineering spectrum. At its very essence, this field is a dynamic fusion of theoretical knowledge and practical application, drawing heavily upon the fundamental principles of physics, the analytical rigor of mathematics, and the intricate understanding of material science.

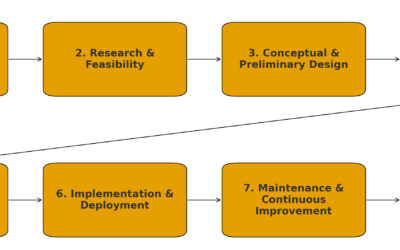

The scope of mechanical engineering is truly vast, encompassing the entire lifecycle of mechanical systems. This begins with the conceptualization and design phase, where innovative solutions are envisioned to address a myriad of challenges. Following design, mechanical engineers are responsible for the meticulous analysis of these systems, ensuring their efficiency, safety, and reliability. This often involves complex simulations and calculations to predict performance under various conditions.

The impact of mechanical engineering is pervasive and profoundly shapes modern society. From the ubiquitous objects of daily life, such as the intricate mechanisms within automobiles that power our transportation, to the energy-efficient designs of household appliances that simplify our chores, mechanical engineers are at the forefront of their creation. Beyond consumer goods, their contributions are critical to the construction of large-scale industrial machinery, which forms the backbone of manufacturing and production across diverse sectors. They also play a pivotal role in the development and refinement of complex energy systems, driving advancements in power generation, distribution, and sustainable solutions.

The Foundation of Mechanical Engineering

Mechanical engineering is rooted in fundamental principles of physics, especially mechanics, thermodynamics, and materials science. It blends theoretical knowledge with practical application, making it one of the most hands-on and versatile branches of engineering.

Key foundational areas include:

- Statics and Dynamics: Understanding the forces on bodies at rest and in motion.

- Thermodynamics: Analyzing energy systems, including heat transfer and the laws of energy conservation.

- Fluid Mechanics: Studying the behavior of liquids and gases in motion or at rest.

- Material Science: Investigating properties of materials and how they respond to stress, temperature, and other conditions.

- Control Systems: Designing systems that behave predictably in response to external inputs.

These principles are applied to the design and operation of machines, engines, robotics, HVAC systems, manufacturing equipment, vehicles, and more.

What Mechanical Engineers Do: Core Responsibilities

Mechanical engineers work across a variety of industries, but their responsibilities often include the following:

1. Design and Development

One of the most prominent responsibilities is product and system design. Mechanical engineers use CAD (Computer-Aided Design) software to conceptualize and draft blueprints for machinery, devices, and mechanical components. The design phase involves:

- Creating 3D models of mechanical systems

- Performing simulations to test strength, thermal properties, or performance

- Considering manufacturing constraints and cost-efficiency

- Selecting suitable materials for the product’s function and environment

Engineers must strike a balance between innovation, reliability, durability, and cost.

2. Prototyping and Testing

Once a design is created, mechanical engineers may oversee or assist in building a prototype. They run various tests to validate the design, such as:

- Stress and fatigue testing

- Vibration and thermal analysis

- Failure mode and effects analysis (FMEA)

- Real-world performance testing

Prototyping and testing are critical for identifying weaknesses before mass production.

3. Manufacturing and Production

Mechanical engineers play a key role in scaling designs for manufacturing. This involves:

- Choosing appropriate manufacturing techniques (e.g., CNC machining, casting, 3D printing)

- Developing processes and assembly lines

- Ensuring quality control during production

- Working closely with technicians and production managers to optimize efficiency

They may also design tools, jigs, and fixtures to aid in assembly or improve manufacturing precision.

4. Maintenance and Operations

In many industries, mechanical engineers are responsible for ensuring that machines and systems operate reliably over time. This includes:

- Predictive maintenance based on condition monitoring

- Root cause analysis of breakdowns or failures

- Retrofitting or upgrading old equipment

- Minimizing downtime and optimizing energy efficiency

In industries like aerospace, automotive, and energy, this responsibility is critical to both safety and profitability.

5. Research and Innovation

Some mechanical engineers work in R&D, pushing the boundaries of what machines and materials can do. Their work often includes:

- Studying new materials such as composites and smart materials

- Exploring advancements in energy systems, including renewable energy

- Developing more efficient engines, pumps, or power systems

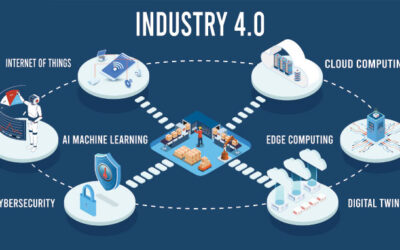

- Incorporating technologies like AI and IoT into mechanical systems

Research engineers often collaborate with cross-disciplinary teams, including electrical, software, and civil engineers.

Common Industries That Employ Mechanical Engineers

Mechanical engineers are in demand across a wide range of industries:

1. Automotive

Mechanical engineers design engines, transmissions, suspension systems, and vehicle components. They also work on electric vehicle (EV) systems, battery integration, and aerodynamics.

2. Aerospace

In aerospace, they contribute to the development of aircraft, satellites, missiles, and space exploration equipment. This work demands high levels of precision, material expertise, and safety standards.

3. Manufacturing

From production lines to industrial robots, mechanical engineers improve efficiency, automation, and quality control in manufacturing plants.

4. Energy and Utilities

Mechanical engineers help design turbines, generators, HVAC systems, and renewable energy infrastructure such as wind turbines or solar farms.

5. Robotics and Automation

They build mechanical components of robotic systems, including arms, gears, actuators, and control mechanisms used in industrial, medical, and consumer robotics.

6. Medical Devices

Mechanical engineers design and test prosthetics, surgical instruments, and diagnostic machines. The work combines biomechanics with high-precision engineering.

7. Construction and Building Systems

They contribute to HVAC systems, elevators, escalators, and plumbing systems in commercial buildings and infrastructure projects.

8. Defense

Mechanical engineers design defense systems, weapons, armored vehicles, and support equipment, often working with government contractors.

Tools and Technologies Used by Mechanical Engineers

Modern mechanical engineers rely on an extensive toolkit, including both physical tools and software solutions.

Software Tools:

- CAD (Computer-Aided Design): AutoCAD, SolidWorks, CATIA, Fusion 360

- CAE (Computer-Aided Engineering): ANSYS, COMSOL Multiphysics

- FEA (Finite Element Analysis): For stress and thermal analysis

- CFD (Computational Fluid Dynamics): For fluid flow simulations

- MATLAB: For advanced mathematical modeling and data analysis

- PLC Programming: For controlling manufacturing and automation systems

Physical Tools:

- Multimeters and sensors

- Oscilloscopes (in mechatronics)

- 3D printers for rapid prototyping

- CNC machines for precision parts

- Testing rigs and lab equipment

Skills Every Mechanical Engineer Needs

To succeed in the field, mechanical engineers must cultivate a wide range of technical and soft skills.

Technical Skills:

- Proficiency in mathematics and physics

- Mastery of mechanical design and simulation tools

- Understanding of thermodynamics, mechanics, and material science

- Programming knowledge (especially for automation and robotics)

- Knowledge of manufacturing processes and standards

Soft Skills:

- Problem-solving and analytical thinking

- Project management and organizational abilities

- Communication skills for collaborating with teams and reporting to stakeholders

- Creativity and innovation mindset

- Adaptability to new technologies and methodologies

Specialized Fields Within Mechanical Engineering

While mechanical engineering is already broad, it contains several highly specialized subfields. These concentrations allow engineers to deepen their expertise and focus on particular technologies or industries.

Acoustical Engineering

Acoustical engineers specialize in the science of sound and vibration. They work on projects involving noise control, sound quality, and acoustic performance. This field applies to audio equipment design, concert hall acoustics, automotive cabin quietness, and even medical diagnostics using ultrasound technology.

Marine Engineering

Marine mechanical engineers deal with systems used in ships, submarines, and offshore structures. They design propulsion systems, refrigeration units, fluid handling systems, and structural components that can withstand the harsh marine environment.

Nuclear Engineering

This field involves designing systems that generate energy through nuclear reactions. Mechanical engineers in nuclear engineering work on reactor design, cooling systems, radiation shielding, and safety mechanisms. Due to the risks associated with radiation, this area requires high levels of precision and adherence to safety protocols.

Microelectromechanical Systems (MEMS)

At the micro-scale, engineers develop MEMS devices such as accelerometers, pressure sensors, and microfluidic pumps. These components are found in smartphones, medical implants, and automotive systems. MEMS design merges mechanical engineering with electrical engineering and material science.

Tribology

Tribology is the study of friction, wear, and lubrication of interacting surfaces in motion. This field is essential in automotive, aerospace, and manufacturing industries where reducing friction leads to better performance, energy efficiency, and component lifespan.

The Global Role of Mechanical Engineering

Mechanical engineering doesn’t operate in a vacuum. It’s closely tied to broader global challenges and opportunities. Engineers in this field play a central role in solving problems that span continents and affect billions of people.

Climate Change and Energy Transition

As governments and corporations shift toward carbon neutrality, mechanical engineers are critical players in redesigning how the world produces and consumes energy. Their contributions include:

- Improving energy efficiency in buildings and factories

- Designing cleaner internal combustion engines and electric vehicle systems

- Engineering solar concentrators, wind turbines, and hydroelectric plants

- Creating more efficient heating and cooling systems for homes and cities

Mechanical engineers are also integral to innovations in carbon capture, hydrogen fuel, and geothermal energy.

Water Access and Sanitation

In developing nations, mechanical engineering solutions can directly impact public health. Engineers design and implement:

- Low-cost water pumps and filtration systems

- Mechanized sanitation systems

- Waste-to-energy infrastructure

- Irrigation systems for agriculture

These systems often need to be robust, low-maintenance, and efficient in off-grid or remote locations.

Space Exploration and Satellite Systems

As space agencies and private companies expand their missions, mechanical engineers are vital in designing:

- Propulsion systems for rockets and spacecraft

- Life support systems in spacecraft and habitats

- Heat shielding and thermal control systems

- Structural components that withstand high g-forces and vacuum conditions

The push toward Mars missions, reusable rockets, and commercial spaceflight all require mechanical engineering ingenuity.

Career Progression for Mechanical Engineers

Mechanical engineering offers diverse career pathways. Whether you’re interested in climbing the corporate ladder, diving deep into R&D, or transitioning into entrepreneurship, the field provides a flexible foundation.

Entry-Level Positions

Graduates typically begin as junior or design engineers, working under the supervision of experienced professionals. Common roles include:

- Mechanical Design Engineer

- Manufacturing Engineer

- Product Development Engineer

- Test or Quality Assurance Engineer

These roles focus on gaining hands-on experience, learning industry-specific software, and understanding organizational workflows.

Mid-Level Roles

After a few years, engineers can take on leadership or project management responsibilities. Mid-career positions may include:

- Senior Mechanical Engineer

- Project Engineer

- Systems Engineer

- Reliability Engineer

Professionals in these roles typically manage larger scopes of work, coordinate teams, and interface more with clients or upper management.

Advanced and Executive Roles

With significant experience, engineers may move into senior leadership, consulting, or innovation roles such as:

- Engineering Manager or Director

- Chief Engineer or CTO

- Technical Consultant

- Product Owner in a tech company

These roles may involve managing large budgets, cross-functional teams, and long-term strategic planning.

Entrepreneurial Opportunities for Mechanical Engineers

The practical nature of mechanical engineering makes it a strong foundation for entrepreneurship. Many engineers leverage their expertise to start businesses that address technical gaps or niche needs in the market.

Product Innovation

Mechanical engineers often create innovative products such as:

- Smart home devices

- Specialized tools or hardware

- Wearable tech

- Fitness and medical equipment

Proficiency in CAD, rapid prototyping, and manufacturing processes enables quick iteration from idea to product.

Engineering Services

Engineers can also start service-based businesses offering:

- Design consulting

- HVAC system optimization

- Energy efficiency audits

- Mechanical prototyping services for startups

By building a reputation in a niche, they can secure clients ranging from local businesses to multinational corporations.

Mechanical Engineering in the Age of Innovation

The role of the mechanical engineer is evolving. Emerging technologies are transforming how mechanical systems are designed, tested, and operated. Some of the biggest trends include:

1. Sustainable Engineering

With global attention on environmental impact, mechanical engineers are now tasked with reducing emissions, improving energy efficiency, and designing recyclable or biodegradable products.

Examples include:

- Designing energy-efficient HVAC systems for green buildings

- Developing fuel-efficient or electric engines

- Innovating in solar thermal or wind turbine technology

2. Mechatronics and Robotics

Mechanical engineering increasingly overlaps with electronics and computer science, forming hybrid fields like mechatronics. Mechanical engineers now build systems that include motors, sensors, microcontrollers, and AI algorithms.

3. Additive Manufacturing (3D Printing)

3D printing has disrupted traditional manufacturing, allowing for rapid prototyping, reduced waste, and more complex geometries. Mechanical engineers must now design parts optimized for additive processes.

4. Digital Twins and IoT

By creating digital replicas of mechanical systems that sync in real time with physical machines, engineers can predict maintenance, simulate performance, and make smarter decisions. This is common in sectors like aerospace and power generation.

5. Artificial Intelligence and Machine Learning

While not traditionally part of mechanical engineering, AI is being integrated into design optimization, fault detection, and system automation, requiring engineers to understand these tools.

Career Pathways and Specializations

As mechanical engineers progress in their careers, they often specialize in specific domains:

- HVAC Engineer: Focuses on heating, ventilation, and air conditioning design and energy efficiency.

- Automotive Engineer: Specializes in vehicle design, engine performance, and safety systems.

- Aerospace Engineer: Works on aircraft and spacecraft design and analysis.

- Manufacturing Engineer: Optimizes production processes and factory layouts.

- Biomechanical Engineer: Applies mechanical principles to medical and biological systems.

- Energy Systems Engineer: Develops renewable and traditional power generation systems.

Others transition into project management, quality control, supply chain optimization, or even executive roles.

Education and Licensing Requirements

Education:

- Bachelor’s Degree: A four-year degree in mechanical engineering is the minimum requirement for most jobs.

- Master’s or PhD: Advanced roles, especially in R&D or academia, may require graduate-level education.

- Certifications: Additional training in software tools, project management, or lean manufacturing can boost job prospects.

Licensing:

In many regions, engineers must be licensed as Professional Engineers (PE) to approve public projects or offer consulting services. This typically involves:

- Earning an ABET-accredited degree

- Passing the Fundamentals of Engineering (FE) exam

- Gaining work experience (usually four years)

- Passing the PE exam