Balancing Cost-Effectiveness and Quality

One of the primary challenges in manufacturing engineering is striking a balance between cost-effectiveness and quality. Manufacturers often operate on thin margins, and the cost of raw materials, labor, and utilities weigh heavily. However, cutting corners to save costs may lead to subpar products. Engineers need to optimize processes, leverage automation and innovative materials, and streamline supply chains to maintain a fine equilibrium between quality and cost-effectiveness.

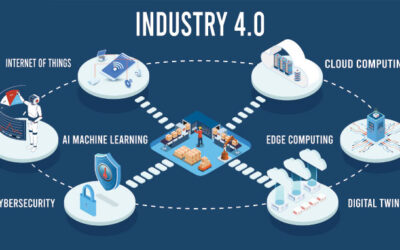

Adapting to Rapid Technological Advances

In an age where technology evolves at breakneck speed, manufacturing systems are incessantly facing the challenge of obsolescence. Engineers need to stay abreast with the latest technological developments and upgrade systems to maintain competitiveness. However, integrating new technologies can be costly and disrupt existing workflows. An incremental approach to technology adoption, coupled with robust change management protocols, can help alleviate these concerns.

Ensuring Sustainability and Environmental Compliance

As sustainability becomes a global priority, manufacturing plants must contend with a myriad of environmental regulations and standards. Engineers have the onus to ensure that manufacturing processes minimize environmental impact, which often requires significant investments in cleaner technologies and waste management solutions. Additionally, there is the challenge of sourcing materials responsibly and ensuring that the entire supply chain adheres to sustainability principles.

Managing Complex Supply Chains

Globalization has led to increasingly complex supply chains that stretch across continents. This complexity brings a host of challenges, from logistics management to geopolitical risks. A prime example of this was seen during the COVID-19 pandemic, where supply chain disruptions led to a global shortage of semiconductors. Manufacturing engineers have to design systems that are resilient and can adapt to fluctuations in the supply chain. Diversifying suppliers, building inventory buffers, and adopting digital supply chain management solutions are some strategies that can be employed to mitigate these risks.

Addressing Workforce Skill Gaps

The advent of advanced manufacturing technologies demands a skilled workforce. However, there is often a gap between the skills required and the skills available in the labor market. Manufacturing engineers face the challenge of recruiting and training employees to operate sophisticated machinery and systems. Partnering with educational institutions, offering apprenticeships, and investing in ongoing training programs are essential steps to address this skill gap.

Ensuring Data Security

Modern manufacturing systems are heavily reliant on data and connectivity. From IoT devices to cloud-based inventory management, data flows through the veins of a manufacturing plant. However, this connectedness also exposes the systems to cybersecurity threats. Manufacturing engineers need to implement robust data security protocols and educate the workforce on best practices to safeguard sensitive information.

Case Study: Tesla’s Manufacturing Challenges

A salient example that encapsulates many of these challenges is Tesla’s journey in scaling up electric vehicle production. The company faced considerable challenges in ramping up production for its Model 3 sedan. Cost overruns, automation complexities, and quality control issues plagued the manufacturing process. Tesla’s ambitious automation led to unforeseen complications, which, in turn, affected production rates and quality.

Elon Musk admitted that they were “over-reliant on automation,” and had to revert to more human involvement in the assembly process. Furthermore, Tesla had to build an entire assembly line inside a tent beside their main factory to meet production targets. The company eventually overcame these challenges through sheer determination, innovation, and an iterative approach to problem-solving.

Navigating the Labyrinth

The challenges faced by manufacturing engineering systems are multifarious and ever-evolving. Engineers must navigate this labyrinth with a combination of innovation, adaptability, and strategic planning. Tesla’s story serves as a reminder that even the most technologically advanced manufacturing systems are susceptible to a gamut of challenges. However, with perseverance and ingenuity, it is possible to surmount these obstacles and pave the way for a robust and sustainable manufacturing landscape.