Quality Unraveled: A Deep Dive into Quality Control for Industrial Engineers

In a fiercely competitive global market, quality is the fulcrum on which a product’s success often hinges. For industrial engineers, mastering the art and science of quality control is paramount. This article unpacks the intricacies of quality control, its methodologies, and illustrates how an industry giant effectively utilizes it.

Decoding Quality Control

Quality control (QC) is a systematic approach to ensuring that products and processes meet predefined standards and specifications. It encompasses a gamut of activities, from inspecting raw materials to testing finished products. For industrial engineers, QC is not merely a set of protocols; it is an ethos that must permeate the entire production process.

Statistical Quality Control

At the heart of QC lies Statistical Quality Control (SQC), a data-driven methodology that uses statistical methods to monitor and control quality. SQC involves collecting data from production processes and analyzing it to identify variances and trends. Industrial engineers use tools like control charts, histograms, and scatter diagrams to monitor key process indicators and make informed decisions.

The Role of Six Sigma

Six Sigma, pioneered by Motorola, is a set of techniques aimed at reducing defects in manufacturing processes. It focuses on identifying and removing causes of defects and minimizing variability. Industrial engineers who are Six Sigma certified, often termed as Green Belts or Black Belts, are adept at employing a data-driven approach to improve quality and process performance. The DMAIC (Define, Measure, Analyze, Improve, Control) framework is integral to Six Sigma.

Total Quality Management

While QC focuses on product quality, Total Quality Management (TQM) is a broader philosophy that extends beyond products to encompass all organizational processes. TQM emphasizes continuous improvement and involves everyone in the organization, from the shop floor to the C-suite. For industrial engineers, implementing TQM means fostering a culture where quality is ingrained in every facet of the organization.

Supplier Quality Management

Quality control begins even before production commences. Ensuring that raw materials and components meet quality standards is critical. Industrial engineers must work with procurement teams to develop supplier quality assurance protocols. This may involve regular audits of suppliers’ facilities, sample testing of materials, and building relationships with suppliers to ensure that quality is prioritized.

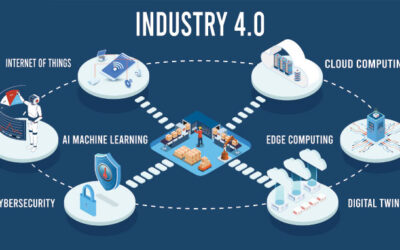

Technology and Quality Control

Advancements in technology have brought forth an array of tools that industrial engineers can leverage for quality control. From high-precision sensors that can detect microscopic defects, to machine learning algorithms that can predict process anomalies, technology is a potent ally in the quest for quality.

Example: Toyota’s Relentless Pursuit of Quality

Toyota, the automotive behemoth, is a quintessential example of quality control in action. The company’s production system, often termed as the Toyota Production System (TPS), is world-renowned for its emphasis on quality.

One of the pillars of TPS is Jidoka, which means automation with a human touch. It involves designing machines and processes that automatically detect defects and halt production. This enables issues to be addressed immediately, rather than allowing defective products to move down the production line.

Another principle that Toyota embodies is Kaizen, or continuous improvement. Employees at all levels are encouraged to suggest improvements, no matter how small. This culture of continuous improvement has enabled Toyota to maintain its reputation for quality, even as it operates at a massive scale.

QC Mantra

Quality control is both an art and a science, requiring a blend of analytical skills, technological acumen, and organizational culture. As custodians of production processes, industrial engineers play a pivotal role in ensuring that quality is not just a checklist, but a mantra that guides every aspect of production.